|

|

|

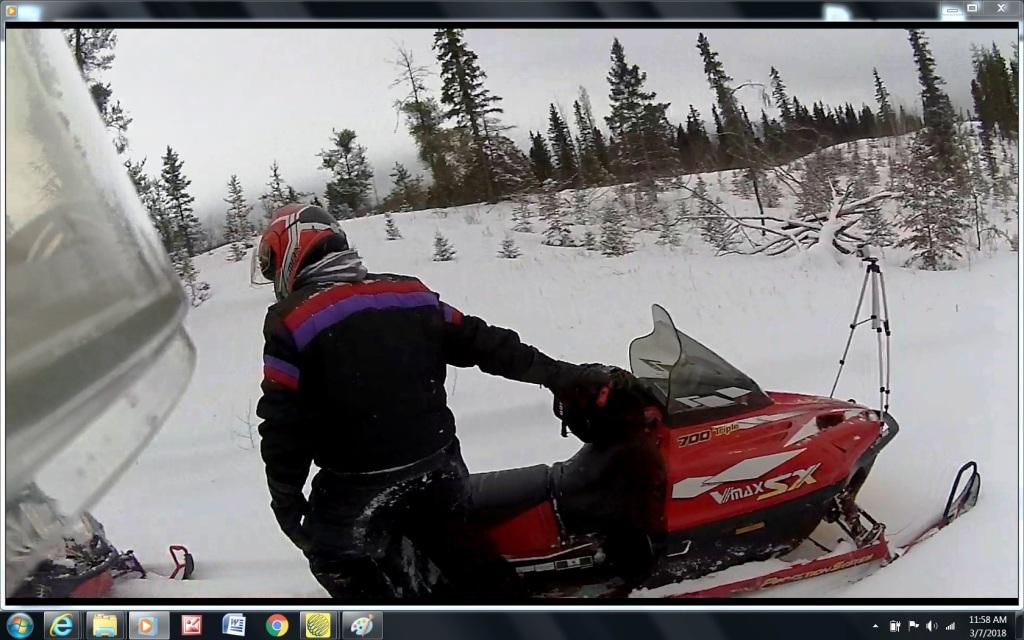

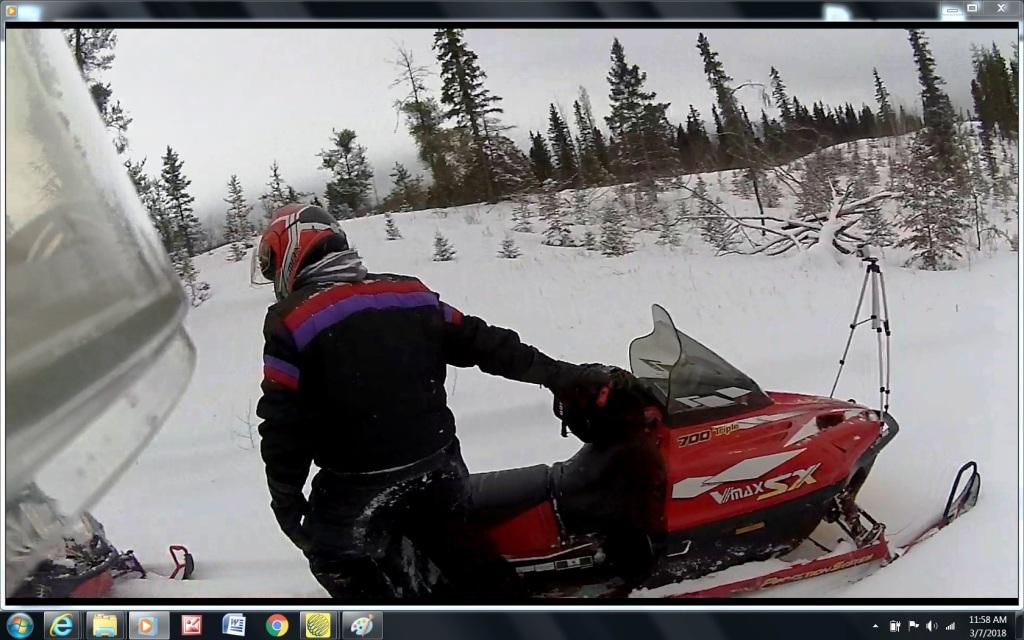

We are parked on

North Branch

for a breather after a BBQ

up in the

NISBET FOREST

on this ride.

|

|

'16 YAMAHA Triple

SXT

700

PROJECT SLED

-

WE

INSTALL SOME "S"

FOR SPORT ON OUR

"XT"!!

SXT

!

-

RECONDITION

A

DESCENT

RUNNING SLED INTO A GOOD BACK COUNTRY TOUR SLED.

-

ADJUST

AND/OR REPLACE THE

COMPONENTS THAT HAVE BEEN POORLY ADJUSTED OR JUST ABUSED.

-

END

UP WITH A SLED THAT HAS EXTREMELY RESPONSIVE HANDLING

AND CAPABLE.

This 700 triple

is equipped with a nice 1.5" track. This sled's reasonably short

track and all temperature responsive 115 HP mill make it a great trail breaker thru the tight NISBET FOREST trails.

|

|

A Parked on a small

Un-named

remote

winter platform in the Nisbet Forest,

good test ride that is revealing an over rev.

A clutch weight change is required to make the engine shift at

8200,

85-8600 is out of the power band with stock cylinders and pipe

18-01V. |

|

Down the road with the sled running great I added different skis,

suspension components and skid plate for cosmetic reasons.

Who said we don't have anything Yellow?

|

|

|

|

We run her hard

for lots of miles after the carburetor reset

and top end freshen up.

16-09V |

|

#1 THE ENGINE RAN.

#2 ON THE ADVICE OF THE PREVIOUS OWNER I TORE THE

TOP END DOWN.

#3 WE PUT HER TO

THE TEST and RUN HER W.O.T. for MILES ON END.

#4 REAR SUSPENSION SHOCK and COUPLER BUSHING SERVICE.

#5 UPGRADE

the TRACK.

#6 OK

TIME FOR THE OEM YAMAHA CLUTCH, and WELL, WE FEEL SHE IS

"Reverse Worthy" SO IN GOES THE REVERSE GEAR BOX......HOLDING MY

BREATH. |

|

#1

THE ENGINE RAN Fall 2015/Winter 2016

When I bought this

sled it fired up and ran. The owner said it needed a set of

pistons that something went wrong on its last ride a number of

years ago. I took some time to analyze it. The engine did sound

like it was missing...but it felt good to pull over on the rope.

I got it home and unplugged the TORs system safety plug and

fired her up, I then proceeded to cut a couple uballs on the ice

with her revving right out and she sounded pretty good! Over the

next month or so, there was a few times it started up good,

cold...then it was hard to start some plugs looking wet some

not. Then it wouldn't start....the plugs were dry, dropping in

some gas it would run again? The engine would be backfiring lean

and smelt like it was running really rich...all at the same

time!!! Could the fuel pump be leaking fuel thru the diaphragm

to the #2 cylinder wetting it down then alternately completely

draining the fuel system out into the crankcase under #2

cylinder? The lack of fuel was making the engine

impossible to start unless fuel was injected manually into one

of the cylinders. A long shot...I have no memory of having to

change a fuel pump on one of our Yamaha's ever....the fuel pump

change was drastic. The sled now starts and runs reliably. The

lean pops were gone but it still felt really rich. The sled was

equipped with an temperature and elevation sensitive fuel

system. After a short run up at one of the vintage oval races I

pulled the carbs apart to see what we have. |

|

a) AS

PURCHASED

|

|

|

|

|

Examining the snaps from KIJIJI carefully it looks like

the track had been changed...the things you notice after

the fact. LOL!! |

b) A

PRELIMINARY PLUG CHECK!

|

It appears the the previous

owner had a hotter BR8 spark plug in the #1 cylinder. It

has a tip extended deeper into the combustion chamber...

|

...where it

would run hotter. I am guessing they had fowling

problems with #1. What else will we find.

|

c) OVER and

OVER, I START THIS SLED OUT IN THE COLD

I start the engine in

the cold looking for consistency...there isn't any! I was going

into the carbs for sure no matter what, but I change the fuel

pump first trying to solve a very unusual lean/rich starting

problem that changes the longer the sled sits, going from

flooded rich, to starting not bad but backfiring to a sled that

will not start at all unless fuel is manually injected thru the

air box. |

|

THE VERDICT

On a whim after experiencing

the bizarre starting characteristics...it turns out

changing the fuel pump was the ticket. It had been

bleeding fuel into the center pulse line lower crankcase

creating all the fickle fun at start up.

Changing the fuel pump

cured this bizarre condition, I assume fuel was running past the

"pumping" diagram thru the "pulse" hose into the center engine

case section below the #2 piston. That is why one cylinder would

be flooded wet and the others dry in a series of different

degrees and stages evident over "various" amounts of

time. The common thread was pulse line location and accompanying

unexplainably a wet cylinder. This must have been driving the

previous owner nuts. |

|

I |

I Look the carbs over and check the choke

adjustment on all 3 carbs. |

d) A QUICK

TEST RIDE

16-05

|

I

FINALLY DIVE INTO THE CARBS

The main jets

right across are richer than I would ever run.

Very surprising I find that the

fuel mixture idle screws that provide

maybe

up to 15% of the total fuel to the engine are

adjusted unlike anything I have ever seen. The fuel

screws were out richer than any spec mentioned. Also all

three carbs had been set with different screw settings

on each carb. The floats were OK. maybe

up to 15% of the total fuel to the engine are

adjusted unlike anything I have ever seen. The fuel

screws were out richer than any spec mentioned. Also all

three carbs had been set with different screw settings

on each carb. The floats were OK.

The fuel screw for #1 was out like

3.5 turns instead of say 2 turns, #2 was out 2.5 turns

rich and #3 cylinder carbs fuel screw was out 2.0 turns

right on spec.

Later when I pulled the head this is what I found for

piston wash.

|

Massive piston wash, richest fuel screw setting and

richest main jet. |

Still a little rich on the

fuel screw, and a little rich on the mains for my

liking, wash not real distinctive, remember this is the

cylinder affected by the fuel draining from the fuel

pump into the crankcase. |

The leanest cylinder in

purchased form, fuel screw on spec (for my main jet

preference) and yes wash indicates she is overall plenty

rich. My set up will minimize wash a small amount. |

|

|

|

#2 ON THE ADVICE OF THE PREVIOUS OWNER I TORE THE

TOP END DOWN Winter 2016

Time to pull her

apart, the Odometer shows 7675KMs and it was disclosed that the

Odometer had stopped some time ago. The owner had bought the

sled told me he added the 1.5" track, new clutch and

several other performance parts including an atmospheric fuel

adjustment system, performance reed valves and reed stuffers. |

|

The engine sounds good but the mileage

really is unknown. |

So off with her head!! |

|

Aside from the crazy

piston wash...a result of real out of spec fuel screw

adjustments

THE ENGINE is

VERY NICE.

|

|

I am looking at

the piston wash once the head is off.

Man what kind of wash is that?

The cylinders exhibit virtually no physically detectable

wear. NICE! |

|

They honed up like new. |

|

The bottom end cleaned up ready for the top end. |

|

|

The gaskets are all hightacked.

|

|

New pistons hanging on the rods. |

|

And yes just like the

kids on the bus...they go up and down! |

|

|

#3

WE PUT HER TO THE TEST and

RUN HER W.O.T. for MILES ON END

A On a very warm

spring day we go for our last ride of the year. It is time to

run this sled hard all day. Like Smokey Yunick would say "Shake

her up in a bag" and lets see what we've got!! Some times

you end up with a Bag of "- - - t", you don't know until you put

her to work.....I know just the way to put her to work

alright...Fox N Hounds with the boys across

Saskatchewan! |

|

I INSTALL A NEW

SET OF PLUGS FOR THE A REAL RUN IN THE NISBET

RUNNING NICE IT

IS TIME TO PUT HER TO THE REAL TEST

16-09

V

|

After our 125Km run I do

a plug check.

|

|

#4 REAR SUSPENSION SHOCK and COUPLER BUSHING

SERVICE Summer 2017 |

|

a) CHAINCASE

BEARING

SERVICE

|

The chain case drive bearings get seals pulled and

greased as well. |

Reinstalling the seal. |

|

Then the snap ring, |

Once A tug on the snap ring

tells us it is seated. |

|

The amount of side slop in the

chain used to help determine how worn it is. I will

examine this more closely in the near future. |

The chain case had a 23 tooth

sprocket over a 40 Tooth for a 1.739 ratio.

|

|

Lower bearing reinstalled. |

I built a dam of grease in the

speedo angel drive housing to contain some light oil. |

|

b) SHOCK and

COUPLER BUSHINGS

|

The main skid frame shock bushings were dry and worn

badly. |

The transfer rods were equally dry and worn. A

replacement bushing is in the pic for comparison. |

|

The upper track idlers are cannot be

changed or serviced with out dropping out the back

section of suspension...so this is the time. Both

bearings were rough. |

I found a couple bearings on the shelf,

one had visibly a good amount of grease, I was

accustomed to finding grease in "this BLUE BRAND". |

|

There is barely visible amount of grease in this "black

bearing". |

Yup "BLUE" has a generous amount of

grease. It is rare to see this. I packed them both

anyways.

|

|

The skid is ready to go in. |

Where the rubber meets the road, so to

speak! |

|

|

#5 UPGRADE

the TRACK

Summer 2017

Part of the

puzzle is upgrading the track for our Nisbet cross country

riding. A lot of opinions is out there but we want a maximum

traction in loose snow and yet something that can be driven on a

groomed trail from time to time....maybe never...but if it

happens! . Also the more snow moving and being carried by the

track the slower the sled will be. This is just plain physics,

we have found that a 121 x 15 x 1.5 is great on our 115HP 700's

and that a 121 x 15 x 1.25 is great on our 100HP 600's.

A few years

earlier I had bought a

1999 V-MAX 700 that was being parted

because aside "the engine", the "track" and 3 of the 4 "shocks", there

was not a single other straight or not cross threaded part on

her!

|

a) TRACK AND

DRIVE AXEL CHANGE

|

The track as purchased was a great 1.5" track but had

been subjected to some unreal abuse just prior to the

sled changing hands.

The 121 x 1.5 that the sled came with is

hard to look at. There were a lot of broken and missing

treads. |

I say this because a lot of paddles or treads

appeared to have been "just freshly" broken off....in fact

running the sled on a test stand at speed the very first

time...resulted in 3 or 4 treads flinging off one was 6 to 8"

wide, ouch don't stand behind this one

|

|

b) NECESSARY TRACK

CHANGE

|

This is the replacement track, a nice 121 x 15 x 1.5"

Polaris/Camoplast

#5411740 |

Having purchased

and salvaged a '99

XT

700 a

few years earlier,

I pulled this track off the

shelf,

-perfect track

-perfect place to use it and

-perfect timing. |

|

|

OUT WITH THE

OLD

|

The main rear skid frame shock is dry and free of

corrosion. The

speedometer did not work on this sled. The original

front drive shaft had a speedo cable broken off in it. I

broke a few tools attempting to extract the debris. |

The track

needed changing and the bearings needed to be packed

with grease so hell lets just do it all! My spare drive

shaft had center drivers only so I pressed the original

outside drive sprockets onto the replacement. |

|

FRONT DRIVE

INSTALL

|

I have changed and installed the front drive. |

It The LT side lower drive bearing

goes back on full of grease. |

|

The axel is in thru the tunnel into the chaincase. |

The LT side lower

drive bearing needs the allen screw locked to the shaft. |

|

|

|

#6

OK TIME FOR THE OEM YAMAHA CLUTCH, and WELL, WE FEEL SHE IS

"Reverse Worthy" SO IN GOES THE REVERSE GEAR BOX......HOLDING MY BREATH

Fall 2017

A On a very warm

spring day we go for our last ride of the year. It is time to

run this sled one more time!

Like Smokey Yunick would say "Shake

her up in a bag" and lets see what we've got!! Sure don't

want to be this guy! Like Smokey Yunick would say "Shake

her up in a bag" and lets see what we've got!! Sure don't

want to be this guy! |

|

A) I EXCHANGE THE

COMET FOR AN OEM CLUTCH

|

This

was interesting...laying the Yamaha clutch, clutch

alignment tool on the SX 700 I found this large offset

to the secondary exists with the Comet clutch

installation. What happens when I install the OEM Yamaha

clutch will be interesting. This

was interesting...laying the Yamaha clutch, clutch

alignment tool on the SX 700 I found this large offset

to the secondary exists with the Comet clutch

installation. What happens when I install the OEM Yamaha

clutch will be interesting. |

|

I

knew this before I rode the sled in the SPRING of 2016.

For that reason I had a used "disposable" belt on the

sled. I do not have a "Comet" clutch alignment tool so

who's to say if this was right or wrong. There was a

hell of a pile of blown belt fragments under the

engine....so no way am I putting a brand new belt on a

"potential" belt eating monster! |

|

Well I did not photo graph it but after installing the

OEM clutch the alignment was still a way off just like

the Comet alignment! I can only guess that "who ever"

installed the Comet believed that the correct alignment

was a pretty serious offset. I have no idea why this

would be right. Is this why there was a pile of blown

belts in the chassis? Once this was discovered we move

the engine back as the photo shows see inset.

Well I did not photo graph it but after installing the

OEM clutch the alignment was still a way off just like

the Comet alignment! I can only guess that "who ever"

installed the Comet believed that the correct alignment

was a pretty serious offset. I have no idea why this

would be right. Is this why there was a pile of blown

belts in the chassis? Once this was discovered we move

the engine back as the photo shows see inset. |

|

b) OUR BABY GETS THE

REVERSE TREATMENT!

|

|